Drafting

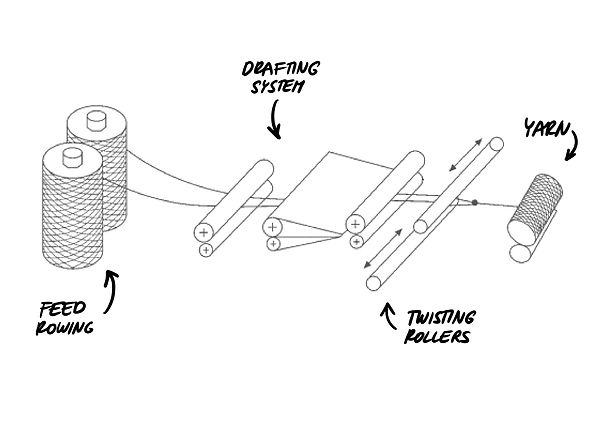

Drafting is the process of drawing out (or attenuating) a fibrous assembly, such as a sliver, top, or roving to form a thinner strand of fibers. The result is a longer, continuous strand of fibers with a lower linear density than before, with fewer fibers in the cross-section, and the threads are straighter and more parallel.

Drafting causes the fibers to slide past each other so that the fibrous assembly becomes longer and thinner. It does not significantly stretch the individual fibers; it merely rearranges their relative positions as they pass through the drafting zone between the two pairs of rollers.

Roller Drafting

This is one of the most common forms of drafting in textile processing is roller drafting.

Roller drafting is performed by passing a sliver or roving between two pairs of driven rollers. The delivery (or front) rollers have a higher surface speed than the feeding (or back) rollers.

The concept of perfect roller drafting is essential. This states that fiber should move at the speed of the back rollers until its leading wool end reaches the front rollers. Once it comes the front rollers, it should be instantly accelerated to the speed of the front rollers. The fiber will be under the influence of the front rollers until the fiber trailing end leaves the front rollers.

If this phenomenon occurred then drafting would be no trouble, however not all fibers in the drafting zone behave according to the requirements of perfect roller drafting. Fiber control is often necessary to improve this situation